Popular Design for Tungsten Carbide Grinding Wheel - Cylindrical Grinding Wheel Of Abrasive Grinding Wheels – YUXINGAN Detail:

Product Introduction

Grinding wheel mainly divided into three categories, A class, B class and W class.

A: mainly used in days of casting, steel, metal processing and stone and other industries.

B: class of major labor, mold industry.

W: Classes are used for precision grinding.

The inner grinding wheel is mainly used for grinding holes, which is one of the most difficult grinding. The outer diameter of the grinding wheel is preferably 60-80%.、

Application

Excircle grinding are the most common grinding ways,which are used on excircle grinder.the outer circle surface of grinding wheels is the working face.the wheels are mainly used for valve,Drive Shaft,bearing etc.According to the material properties, surface quality and geometric precision of the workpiece, the matching grinding wheel can be chosen to the performance .

Type Code

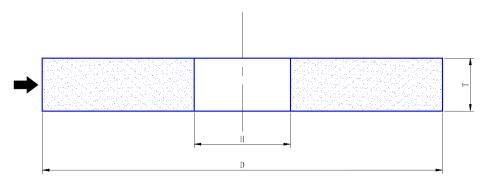

Type Code: 1

|

OD |

T |

H |

Grit |

Grain |

Hardness |

Structure |

Speed |

|

250mm |

20mm-40mm |

75mm 76.2mm 127mm |

A WA AA 38A 25A PA SA GC C |

F36 F46 F54 F60 F80 F100 F120 |

K L M N P Q |

5 6 7 8 9 10 |

33m/s 35m/s 40m/s 45m/s 50m/s 60m/s |

|

300mm |

20mm-63mm |

75mm 76.2mm 127mm |

|||||

|

350mm |

25mm-63mm |

||||||

|

400mm |

32mm-80mm |

127mm 203mm 203.2mm |

|||||

|

450mm |

|||||||

|

500mm |

203.2mm 254mm 304.8mm |

||||||

|

600mm |

40mm-150mm |

||||||

|

750mm |

50mm-75mm |

305mm |

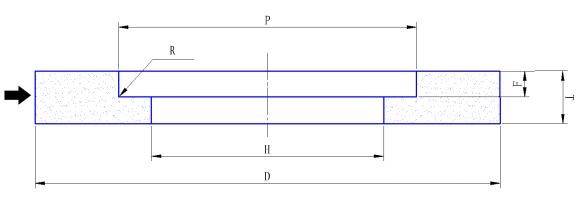

Type Code: 5

|

OD |

T |

H |

P |

F |

R max |

Grit |

Grain |

Hardness |

Structure |

Speed |

|

300mm |

40mm 50mm |

76.2mm 127mm |

150mm 190mm |

13mm |

3.2 |

A WA AA 38A 25A PA SA GC C |

F36 F46 F54 F60 F80 F100 F120 |

K L M N P Q |

5 6 7 8 9 10 |

33m/s 35m/s 40m/s 45m/s 50m/s 60m/s |

|

350mm |

127mm |

215mm |

13mm |

5 |

||||||

|

400mm |

||||||||||

|

450mm |

40mm-80mm |

127mm 203mm 203.2mm |

215mm 280mm |

13mm25mm | ||||||

|

500mm |

203mm 203.2mm 304.8mm 305mm |

400mm |

13mm 25mm 50mm |

8 |

||||||

|

600mm |

40mm-100mm |

|||||||||

|

750mm |

63mm-100mm |

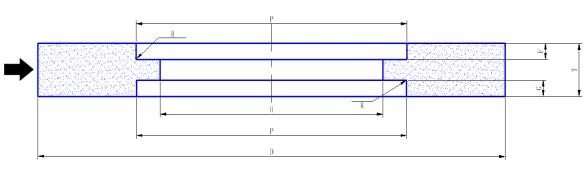

Type Code: 7

|

OD |

T |

H |

P |

F |

G |

R max |

Grit |

Grain |

Hardness |

Structure |

Speed |

|

300mm |

40mm 50mm |

76.2mm 127mm |

150mm 190mm |

6mm-10mm |

3.2 |

A WA AA 38A 25A PA SA GC C |

F36 F46 F54 F60 F80 F100 F120 |

K L M N P Q |

5 6 7 8 9 10 |

33m/s 35m/s 40m/s 45m/s 50m/s 60m/s |

|

|

350mm |

127mm |

215mm |

10mm-13mm |

5 |

|||||||

|

400mm |

|||||||||||

|

450mm |

40mm-80mm |

127mm 203mm 203.2mm |

215mm 280mm |

8 |

|||||||

|

500mm |

203mm 203.2mm 304.8mm 305mm |

400mm |

|||||||||

|

600mm |

50mm-100mm |

10mm-25mm |

|||||||||

|

750mm |

80mm-100mm |

||||||||||

Product detail pictures:

Related Product Guide:

We enjoy a very good reputation among our customers for our excellent product quality, competitive price and the best service for Popular Design for Tungsten Carbide Grinding Wheel - Cylindrical Grinding Wheel Of Abrasive Grinding Wheels – YUXINGAN, The product will supply to all over the world, such as: Angola, The Swiss, Guatemala, We supply professional service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound products with good logistics service and economical cost. Depending on this, our products are sold very well in the countries in Africa, the Mid-East and Southeast Asia. Adhering to the business philosophy of ‘customer first, forge ahead', we sincerely welcome clients from at home and abroad to cooperate with us.

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.

-

2021 High quality Flap Disc Grinding - Metal A...

-

Cement Mixer - Fast delivery China Putzmeister...

-

China Factory for Bevel Gear Grinding Wheel - ...

-

Special Design for Abrasive Grinding Wheels - ...

-

2022 wholesale price Flat-Top Tower Cranes - Q...

-

Personlized Products Gear Grinding - Aluminum ...