-

Grinding Wheel For Aluminium

This product is made up of high-strength fiber mesh, ground ore and special adhesive.

This product is made up of high-strength fiber mesh, ground ore and a special adhesive.

Used for medium power angle machines, reach excellent grinding performance even under the condition of low contact pressure.

Used for high stress working, excellent abrasive performance, high stability in grinding pipe.

The metal grinding disc provides a high burr removal capability of the general types of iron and steel to give maximum performance and long life.

Grinding general mild steel for maximum durability.

-

Centreless Grinding Wheel For Grinding Piston Rods

Conventionally grinding is characterized as low material removal process capable of providing both high accuracy and high finish. However, advent of advanced grinding machines and grinding wheels has elevated the status of grinding to abrasive machining where high accuracy and surface finishas well as high material removal rate can be achieved even on an unhardened material.

-

Hypodermic Needle Grinding Wheels

This product is widely used in stainless steel, copper, aluminum and other metals and glass, furniture, ceramics, marble and other non-metal fine polishing.

-

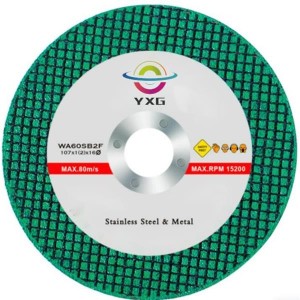

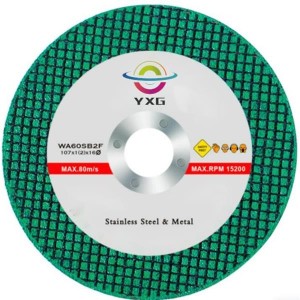

Super-thin Cutting Disc

Ultra-thin cutting discs with ultra-fast cutting performance and minimal burrs.

Ideal for cutting metals, stainless steel, ferrous metals, non-ferrous metals, marble and concrete.

Proprietary alumina particle combination.

Our Metal cutting disc is widely used in metal cutting in automobiles, ships, railways, construction, stainless steel, and other industries. And we have cutting disc size 105 mm-400 mm, 4 inch-16 inch.

-

Cylindrical Grinding Wheel Of Abrasive Grinding Wheels

Grinding wheel mainly divided into three categories, A class, B class and W class.

A: mainly used in days of casting, steel, metal processing and stone and other industries.

B: class of major labor, mold industry.

W: Classes are used for precision grinding.

The inner grinding wheel is mainly used for grinding holes, which is one of the most difficult grinding. The outer diameter of the grinding wheel is preferably 60-80%.、

-

Grinding Wheel Used On Engine Valve End-Face

Resin bond is the most common choice for diamond and cubic boron nitride superabrasive wheels. Form a bonding structure to keep the grinding wheel cutting sharp, with high surface finish, high grinding efficiency, and low heat generation. The most important thing is that it is very cost-effective. It is more competitive than ceramic bond and metal bond. Therefore, it is widely used in the grinding industry. Diamond has a better effect on cemented carbide, and CBN has a better effect on HSS.

-

White Aluminum Oxide Bearing Grinding Wheels

The grinding wheel used to cut the raceway of the bearing adopts high-quality mixed abrasives and special-performance binders to form fine pulverization characteristics in the grinding abrasives and maintain its cutting edge performance. At the same time, the bonding agent has good bending strength and small mold elasticity, the modified shape is easy to maintain, and the grinding accuracy of the raceway can be guaranteed.

-

Abrasive Tools Grinding Wheels For Grinding

The tool grinding wheel is mainly used in the manufacturing and most of them are taper wheel,straight cup wheel,dish wheels and other un regular shape wheels.the characteristics of uniform structure,good self-sharpness and long service life.

-

Horizontal Surface Grinding Wheels

This product can be used for surface grinding machine. It is suitable for surface grinding of various industries. According to the material properties, surface quality and geometric precision of the workpiece, the matching grinding wheel can be chosen to the performance .